English

English

2025.02.12

With the innovation of Mini and Micro LED products and the expansion of market share, the competition between COB and MIP technologies has become increasingly intense. The choice of packaging technology is crucial for the performance and cost of Mini and Micro LEDs. What are the differences between SMD, COB and MIP? Which type of LED display should we choose?

The traditional SMD (Surface Mount Device) technology involves packaging individual RGB (red, green, blue) LED chips into LED lights. These lights are then soldered onto a PCB (Printed Circuit Board) using SMT (Surface Mount Technology) solder paste to create unit modules, which are finally assembled to form a complete LED display.

COB, short for Chip on Board, refers to the process of directly soldering multiple RGB chips onto a single PCB (Printed Circuit Board). These chips are then encapsulated with a unified coating to form unit modules, which are subsequently assembled to create a complete LED display.

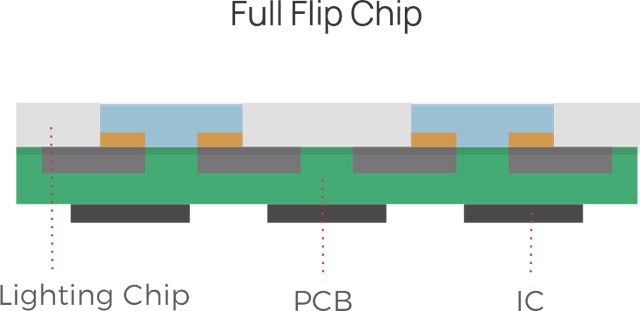

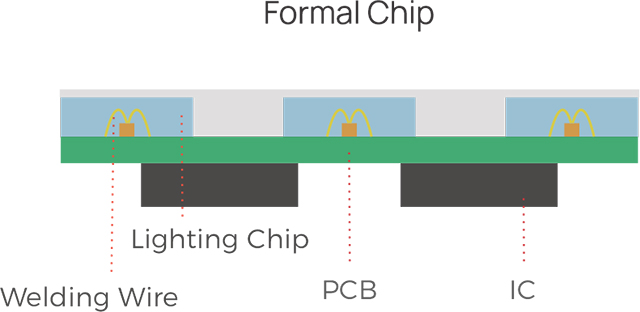

COB packaging can be classified into formal chip COB and flip chip COB. Formal chip COB has limitations in terms of the viewing angle and wire bonding distance, which restricts the performance development of the product. Flip chip COB, an upgraded version of formal chip COB, enhances reliability, simplifies the production process, provides better display effects, and offers an exceptional near-screen experience. It achieves a true chip-level pixel pitch, reaching Micro LED standards, and surpasses traditional SMD products in terms of high brightness, high contrast, black uniformity, and display stability. However, since COB screens cannot sort individual LED lights based on similar optical performance like SMD screens, they require calibration of the entire screen image before leaving the factory.

With advancements in industry technology, the cost of COB packaging has been on a downward trend. According to industry experts, in the P1.2 pixel pitch segment, COB prices have already fallen below those of SMD technology products, and the price advantage is even more pronounced for smaller pixel pitch products.

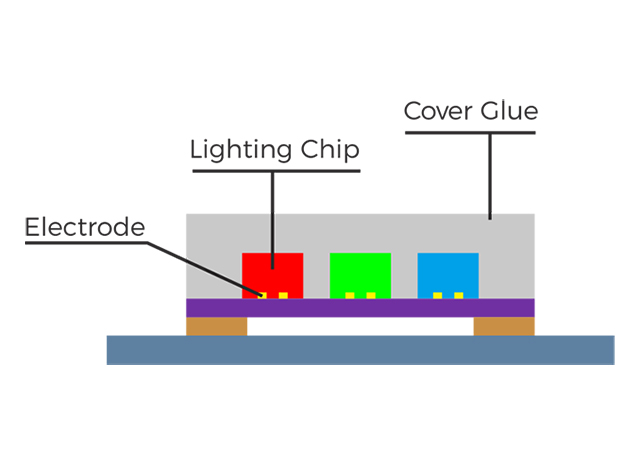

MIP, which stands for Mini/Micro LED in Package, refers to the process of cutting the LED panel into segments to create individual devices or multi-in-one devices. After optimizing for light dispersion and mixing, these components are soldered onto a PCB using SMT (Surface Mount Technology) with solder paste to form LED display modules.

The MIP solution achieves color consistency by employing full-pixel testing and blending similar pixels, meeting cinema-level color gamut standards (DCI-P3≥99%). During the process of light dispersion and color separation, defective pixels are identified and eliminated, ensuring a high yield for each pixel point during final transfer, thus reducing repair costs. Additionally, MIP offers better compatibility, making it suitable for various substrates and pixel pitch applications, and is compatible with medium to large-sized Micro LED display applications.

GOB, which stands for Glue on Board, is a response to the increasing demands for product quality and display performance. It is commonly referred to as "encapsulation of the LED surface."

The emergence of GOB meets market demands and offers two significant advantages. Firstly, GOB provides an ultra-high protection level, making it resistant to water, humidity, impact, dust, corrosion, blue light, salt, and static electricity. Secondly, its frosted surface effect facilitates the transition from point light sources to surface light sources, increasing the viewing angle and enhancing color contrast. This effectively eliminates moiré patterns, reduces visual fatigue, and results in a more refined display quality.

In summary, SMD, COB, and MIP packaging technologies each have their own advantages and disadvantages. It is crucial to choose the appropriate technology based on different application scenarios and requirements. LPDISPLAY offers a comprehensive range of products and holds multiple patents both internationally and domestically. With extensive project experience in LED fine pitch displays, the company is committed to empowering a wider array of scenarios with a richer and smarter matrix of new display products. LPDISPLAY's products are widely used across various industries, including command centers, surveillance and security, commercial advertising, sports events, home theaters, and virtual production.

With technological breakthroughs and continuously decreasing costs, Mini and Micro LED are poised to make significant impacts in various fields. The choice between the increasingly popular COB and MIP technologies is more about differentiation than replacement. At LPDISPLAY, we carefully consider our customers' diverse needs to offer tailored solutions. If you have further insights or requirements, feel free to leave a comment and join the discussion!